- Home

- »

- Products

- »

- Conveyor Systems

- »

- Drip oiler

Drip oiler

For lubricating the chains on the conveyor

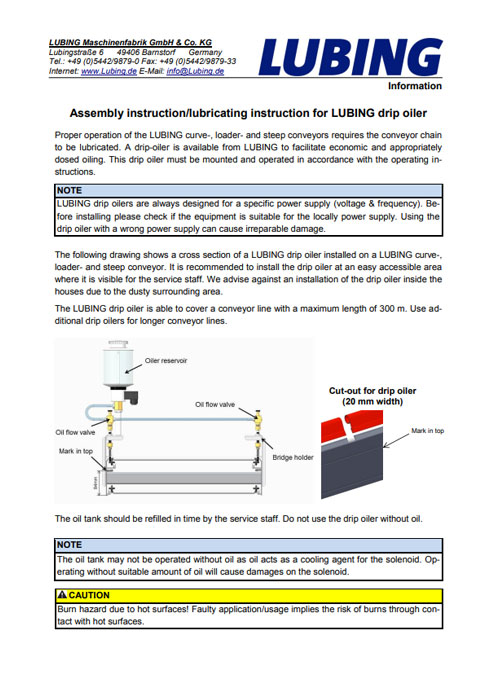

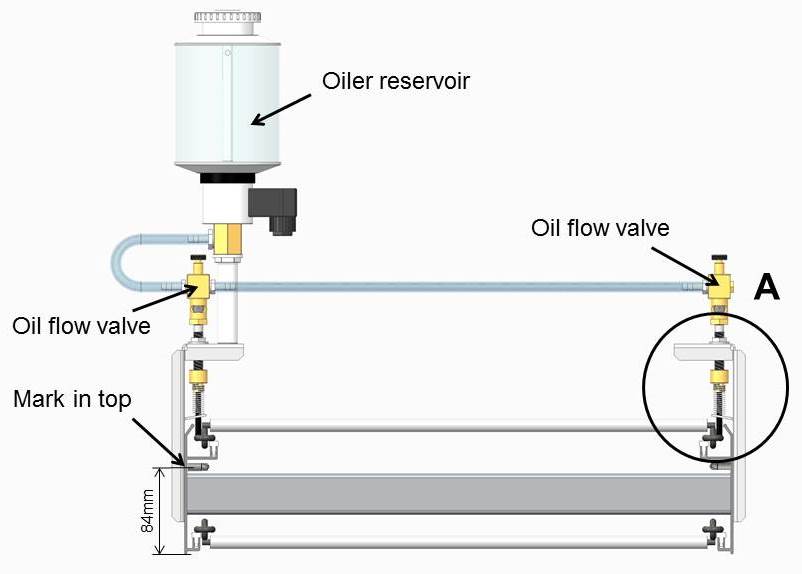

For conveyor systems, it is necessary to oil the conveyor chains. A drip-oiler is available from LUBING to facilitate economic and appropriately dosed oiling.

This is available in different voltages.

It is recommended to link the drip oiler’s power supply with the used motor’s power supply. In this way, it is guaranteed that the drip oiler is only operating while the conveyor system is running.

Furthermore, the supply line should integrate a manual switch (on / off) or a time relay. The dripping oil can thus be connected as required.

We recommend installing the drip oiler in an easily accessible area visible to the service staff. We advise against installing a drip oiler inside the bird area due to the dusty surrounding area.

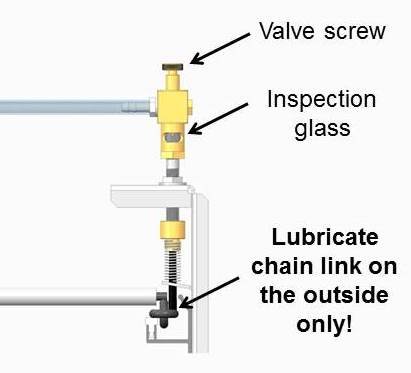

The oil flow valves should be set so that a drop of oil falls every 5 sec. The adjustment is made by turning the valve screw. The period between two drops of oil can be observed in the inspection glass.

The conveyor system must not be over-lubricated. Too much oil binds dust and dirt and can hurt the quality of the eggs. The economic application of oil ensures that the eggs transported do not come into contact with the oil. Nevertheless, the oil used must be classified as food-safe.

Too little oil leads to increased friction in the conveyor system makes the conveyor challenging to move, and leads to premature wear.

The position of the oil brush is critical. The oil brush may only oil the flat chain link on the outside.

Optional accessories

Float switch

The float switch integrated into the drip oiler bottom checks the oil level within the oil container. If the oil level falls below a certain level, the drip oiler will switch off automatically. An operation of the system without oil can cause irreparable damage. We recommend using a drip oiler bottom with a float switch to avoid this.

We suggest redirecting the signal of the float switch to the central control unit. If a low oil level light indicator is triggered, the conveyor system can be stopped in case of insufficient lubrication. The drip oiler bottom with float switch can only be used for all drip oilers distributed by LUBING.

Uni Control

The electronic drip oiler timer allows an exact adjustment of time intervals for lubricating the LUBING conveyor system. During the operation of the conveyor system, the drip oiler is switched automatically. This guarantees an even and reliable lubrication. Defining the start and stop time within 0.1 seconds to 99 hours is possible. We recommend using shorter intervals than those used for manual lubrication.